Two ongoing challenges seen across the business world are how to transition our military veterans into stable and worthwhile civilian careers, and how to fill the tremendous gap in the workers we need with advanced technical skills. With their Academy of Advanced Manufacturing, Rockwell Automation and ManpowerGroup are tackling both problems at once.

Established in 2017, the AAM provides a free 12-week program in industrial automation for select military veterans, covering both the technical and professional skills needed for success. Classes are held on-site at the Milwaukee headquarters campus and the Cleveland offices of Rockwell Automation, a world leader in industrial technology employing over 28,000 people in more than 100 countries, with annual revenues of nearly $8 billion. To recruit candidates and deliver the program, Rockwell partnered with global workforce solutions provider ManpowerGroup. Also headquartered in Milwaukee, ManpowerGroup has about 30,000 employees in more than 75 countries.

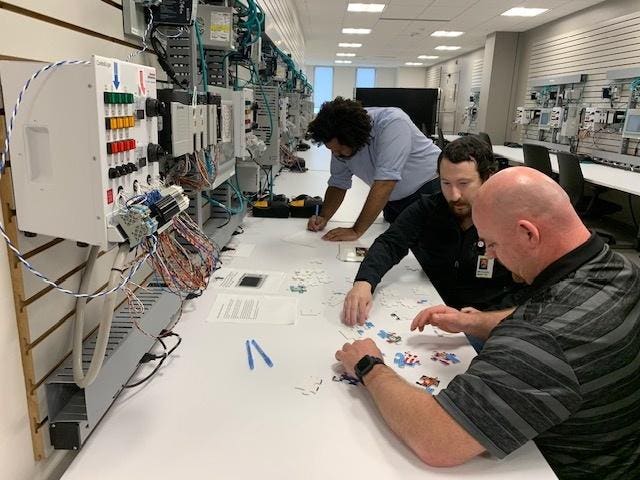

The AAM begins by recruiting veterans with proven technical abilities, then providing them with manufacturing-specific controls training in areas such as interpreting wiring diagrams, servicing factory electro-mechanical components, and troubleshooting and servicing programmable logic controllers, the computers that run industrial systems. The program’s graduates receive Instrumentation and Automation Control Technician certification from Rockwell.

In addition to charging students nothing for the program, the AAM provides additional financial and other assistance. “It has five pillars of success,” said Tony Lawrence, ex-Army Ranger and program manager – AAM for ManpowerGroup. “First, it doesn’t use any GI Bill money. Second, it pays for all student hotel bills. Third, it pays for their food. Fourth, it pays them weekly to do the program–not a lot, but something. And fifth, it brings companies to the candidates.”

Indira Tapias attended the program in summer 2021 and is glad she did. “I come from an electrical background in the Navy, working on FA-18 aircraft,” she said. “I was in school finishing pre-med and not finding the jobs I needed when I heard about this. It has definitely completely changed my life. I’ve been in my career for two years now, and I don’t see myself leaving it. In this industry, there are a lot of retirements coming up and automation is getting more and more technical, so there are lots of opportunities. I’m already able to do a lot more than what I was taught, in part because of the soft skills they taught as well.”

“We’re developing a program that has identified the ideal candidate for this workforce,” Lawrence said. “Vets are adept at teamwork and have pre-existing technical skills. Plus they have the ability to digest very difficult material quickly.”

Recruiting companies are seeing the benefits as well. One example is Schwan’s Company, the Minnesota-based food company with brands such as Red Baron and Tony’s pizzas and Mrs. Smith’s pies. “It came to us by way of one of our engineers in late 2017,” said Jennifer Brantley, director of HR for Schwan’s in Salina, Kansas, and Stilwell, Oklahoma. “We began to reach out to Rockwell and find out about the program and how they were sourcing students. We were getting ready to spend big dollars on automation.”

“We recruited our first AAM student in 2019,” said Chris Wiseman, senior director of manufacturing at the company’s Salina, Kansas, pizza plant. “We have a facility that’s been here since the 1970s that has been through many changes, which needed new equipment to support the business. On the horizon was a new greenfield facility, probably the most automated pizza facility in the world. We had some very specific needs for technical resources as a result.”

“We’re using platforms they’re used to,” added Brantley. “For example, we use Allen-Bradley controllers [one of Rockwell’s product lines]. Plus, students have an additional year of AAM support after they come to us.”

“Schwan’s is growing, and filling these types of highly technical roles is a real challenge,” said Taber Rigg, VP of HR, global supply chain for Schwan’s. “In some cases, these jobs are the most technologically advanced food production jobs in the industry. The partnership has helped us find extremely qualified individuals to fill these roles.”

With the program well-established and the initial curriculum proven, the next question for AAM is how to serve more students. “We’re at an inflection point,” explained Phil Bush, business development manager, AAM at Rockwell Automation. “We feel like we’ve built a robust curriculum and sustainable recruiting and hiring processes. We’ve had 457 students sign up for the program, and 373 have graduated. Of our graduates, 90% went on to work for our customers. For our veterans, those are very sustainable and career-oriented roles. Now we also want to put the program into a position where we can expand.”

The current challenge is that all students right now are required to attend classes in either Milwaukee or Cleveland, which can be a deal-breaker for some otherwise eligible participants. “We would love to move beyond where we are now,” Bush continued. “We’d like to develop the ability to source local, train local, and hire local. We’re investigating partnering with technical colleges to make that happen.” The AAM is also partnering with companies to offer upskilling training for existing workforce members, for veterans and non-veterans alike.

“We see a real need to expand this type of program to help fill our growing need of more advanced technical skills,” Rigg said. “We are exploring ways to bring this program closer to our facilities to help develop our local talent and further grow their careers.”

In the meantime, the AAM is helping with a hiring need that’s become critical across the country. “No matter what the industry, labor is at the crunch level,” said Wiseman. “This area of skills has a high vacancy rate. This partnership has helped with that crunch.”

It’s a crunch that will likely become even more complicated over time. “That workforce is going to continue to evolve,” said Bush. “AI and machine learning will transform the work and the workforce needed. We want our program to be part of how you evolve the workforce to match those needs.”

Read the full article here